SEPTOMAX® // Multiple-joint hinges & Kinematics solutions

"Connect & Move" on the basis of innovative multi-link functions

... directly to product page // www.septomax.com

About SEPTOMAX® // Concept & Technical Details

Novel connection options with hinges with "multi-pivot"

Modern attachment solutions are increasingly demanding technical flexibility as well as the visual appeal of hinge products. In particular, high degrees of freedom are required in the design of end products, which can only be realized by complex hinge solutions and also enable the connection of asymmetrical flaps, doors or hatches as well as the design of individual kinematics and variable opening angles.

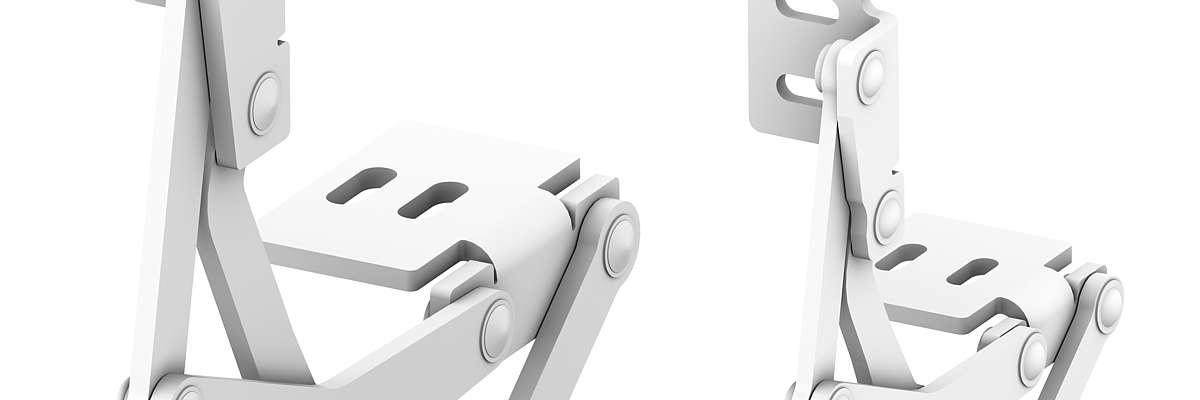

The patented SEPTOMAX® series meets these requirements on the basis of its variable multi-joint design. A multi-link principle developed on the basis of current CAD and simulation software, which is installed completely inside and can be used both as a standard as well as in a special design for all industries, sectors and sectors. SEPTOMAX multi-joint hinges have the following technical specifications:

- Fully internal mounting and up to 180 or 270 degrees opening angle

- Concept "multi-joint" allows new kinematics / connections beyond standard hinges with single pivot

- Opening angles and movement sequences can be individually and complexly designed

- Depending on requirements, can be designed as a four-, seven- or multi-pivot version

- Made of stainless steel, steel (optionally coated) or aluminum

- Available as a standard product or as a customer-specific special construction

- Suitable for low loads up to heavy loads

- Can also be used with additional gas spring mounting or any detent systems

- Sample preparation in serial version or as a 3D print version

- Various sizes available; Based on maintenance-free components

- CAD & ASOMv7 and tested in continuous running tests.

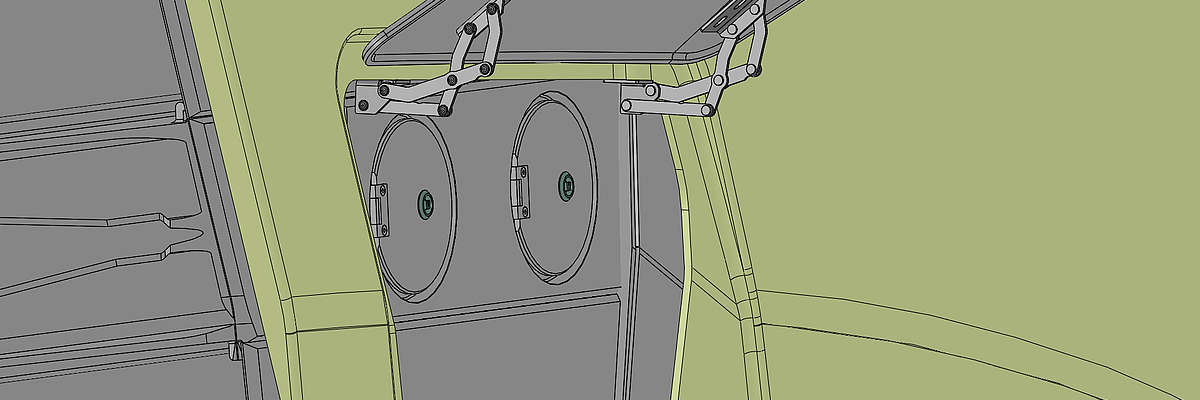

- SEPTOMAX principle can also be used beyond pure hinge applications (including lifting / tilting systems)

With SEPTOMAX products, connections can be realized in this respect, which until now were not feasible with conventional hinges based on a pivot point; Multi-hinge hinge therefore extend the application range of conventional hinge types; flexible ...

... for detailed specifications & product details // www.SEPTOMAX.com

SEPTOMAX® // Applications & Assortments

Industry-independent solutions for all hinge applications or pure pan systems

The SEPTOMAX product series has emerged from a cross-sectoral trend towards variable and functionally open hinge solutions. Whether it is the more rounded and asymmetrical car bodies in the vehicle industries, gap-free surfaces in the furniture and design sector or heavy load connections with specific kinematics, the most important thing is the combination of "shape & function" with adequate hinge solutions.

Therefore, SEPTOMAX products are contemporary alternatives that provide a flexible and high-quality solution to meet the needs and requirements of all sectors where design freedom and design diversity of end products are the focus; Both for horizontal and vertical connections. Our core facts about SEPTOMAX Industry & Application:

- Free industry-open application areas (industry, crafts, trade / distributors and private users)

- Suitable for any connection of flaps, doors, floor & ceiling hatches

- For all types of attachment: Bearing, inlaid or "mitred"

- Various versions for high visual-technical requirements up to robust load versions

- Available in the smallest number of parts to the industrial series

- For smooth surfaces (gap-free)

- According to fully certified requirements (ISO 9001: 2015) and REACH compliant

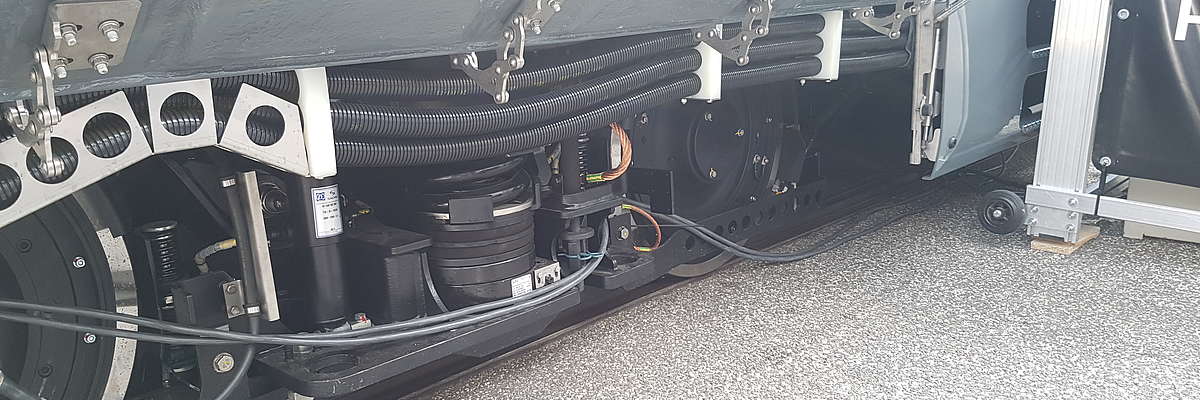

Our selected example industries include: Vehicle industry, buses, rail transport, architecture, furniture / showcases, shop and window construction, medical technology, mechanical engineering, construction machinery, leisure industry, cabin construction, environmental technology, polymer technology, locksmithery / carpentry, construction offices, mobile homes, container construction, lighting technology , Shipbuilding & yacht building ...

... directly to the assortments & application possibilities // www.SEPTOMAX.com

SEPTOMAX® // Construction, Quality Assurance & References

Demand-based added value based on adapted technologies

Product ranges from Emil Kaltenbach are quality products entirely "Made in Germany"; This also applies to complex SEPTOMAX multi-joint solutions. Our design process is CAD based and secured by ASOMv7 simulation software. Product specifications are incorporated into our design as well as technical restrictions resulting from the respective application.

In manufacturing, we use laser and / or punching of the individual boards, use a rivet and bushing technology adapted to our specific requirements as well as corresponding manufactured packaging materials. The entire value-added process is monitored in accordance with the requirements of ISO 9001: 2015, quality and inspection-oriented.

As a design service, we also provide our customers and prospective customers with know-how from our development department. Feasibility analyzes, tests of individual customer specifications or the adaptation of hinges to minimal installation environments are examples of constructive theft.

As a result, SEPTOMAX series are used today by renowned customers from a wide range of sectors for various applications; Please have a look at our example references.

Thank you for your interest in our Septomax short introduction. We look forward to your visit on our main page // www.SEPTOMAX.com